Industrial integrated machine for power supply and distribution industry

From the perspective of power supply and distribution, a large number of electricity users lack professional knowledge of electricity use, and there are more potential safety hazards in electricity use. Leakage current constitutes a potential danger to patients. Power failure can cause equipment to be used and urgently needed to treat patients. Danger to life. For more special units like hospitals, the power supply load level is higher, and the power supply and distribution methods are quite different from other civil buildings. There are many kinds of high-power instruments and equipment, and electricity safety precautions are more important. According to the current application of intelligent and networked power distribution in China, the application of intelligent power distribution system in the entire power distribution system is becoming more and more important. With the continuous development of communication technology and software technology, intelligent The power consumption monitoring of the industrial all-in-one power distribution system will play a positive role in improving the power consumption level of hospitals and other special places.

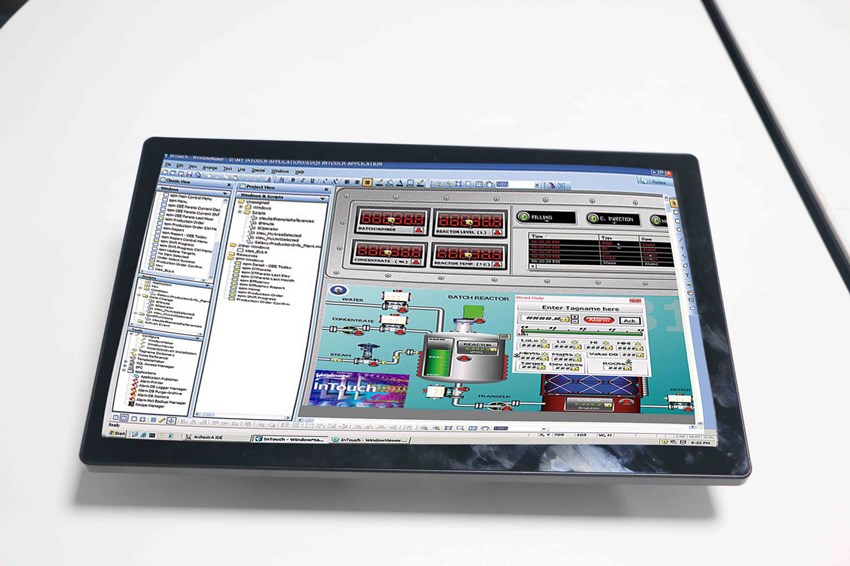

Power management industrial computer or power monitoring instrument sensor, which mainly monitors three-phase voltage, current, active power, reactive power, power factor, frequency, electrical energy, load analysis, reasonable dispatch, remote control closing and opening, peak and valley filling and other data, through RS-485 interface, using international standard communication protocols such as Modbus to transmit data. At the same time, the Qianhai Gaole industrial control all-in-one computer can also analyze the energy consumption of electrical equipment, collect the electricity consumption of each electrical equipment, and send it to the monitoring terminal, and then use the intelligent display monitoring terminal to display, the user can clearly Understand the electricity structure in the environment, so as to make a reasonable plan for the later electricity consumption. The management center has integrated functions such as real-time monitoring, abnormal accident alarms, event recording and printing, collation and printing of statistical reports, electrical energy cost management and load monitoring, etc., so that the equipment can be operated according to the best use, ensuring electricity and safe use of electricity.

Higole’s power station cabinet solution can effectively combine IT equipment with intelligent power plant management. The Qianhai Gaole industrial control all-in-one computer adopts a fully enclosed fanless design, an aluminum alloy shell, and an excellent heat dissipation effect, which can ensure the stable and efficient operation of the front end of the 7*24 hours power supply system. It supports multiple Ethernet ports/WiFi to realize the network wake-up function, and the interface can be customized. The product has strong compatibility and strong industrial-level performance, which can adapt to the very harsh operating environment of power plants. Assist power plant smart operation management, smart maintenance and safety, smart new energy power generation, etc., enhance the core competitive advantage of power plants, and promote the sustainable development of power plants.

The application of the Higole industrial control integrated computer in the power control cabinet can effectively connect the entire power plant. As a unit in the system, you can view system-related data, and at the same time control the operation of the power control machine itself, intelligent management, and improve the overall system Operation efficiency, consumption reduction and energy saving, and better use of the advantages of energy stations.