Industrial computer integrated computer power transmission automation monitoring case

Transmission lines are an important part of the national grid. Due to the large span of transmission lines, usually spanning hundreds of kilometers, they are very vulnerable to various environments and lead to power supply failures. Therefore, it is necessary to regularly monitor the operation status of the transmission line. At present, the manual line inspection method is generally used to meet this requirement. However, the transmission line has a large longitudinal span, a complex distribution terrain, and a wide variety of line state parameters. It is difficult to achieve a unified and centralized system. Management, and the most difficult problem is that there are many links in the transmission line that are not easy to be discovered, and the state of the line cannot be grasped in time. Generally, the problem is dealt with after the fact, and it is difficult to effectively prevent it in advance. Therefore, an automatic, accurate and real-time monitoring method is required to realize all-weather online monitoring and management of the status of transmission lines.

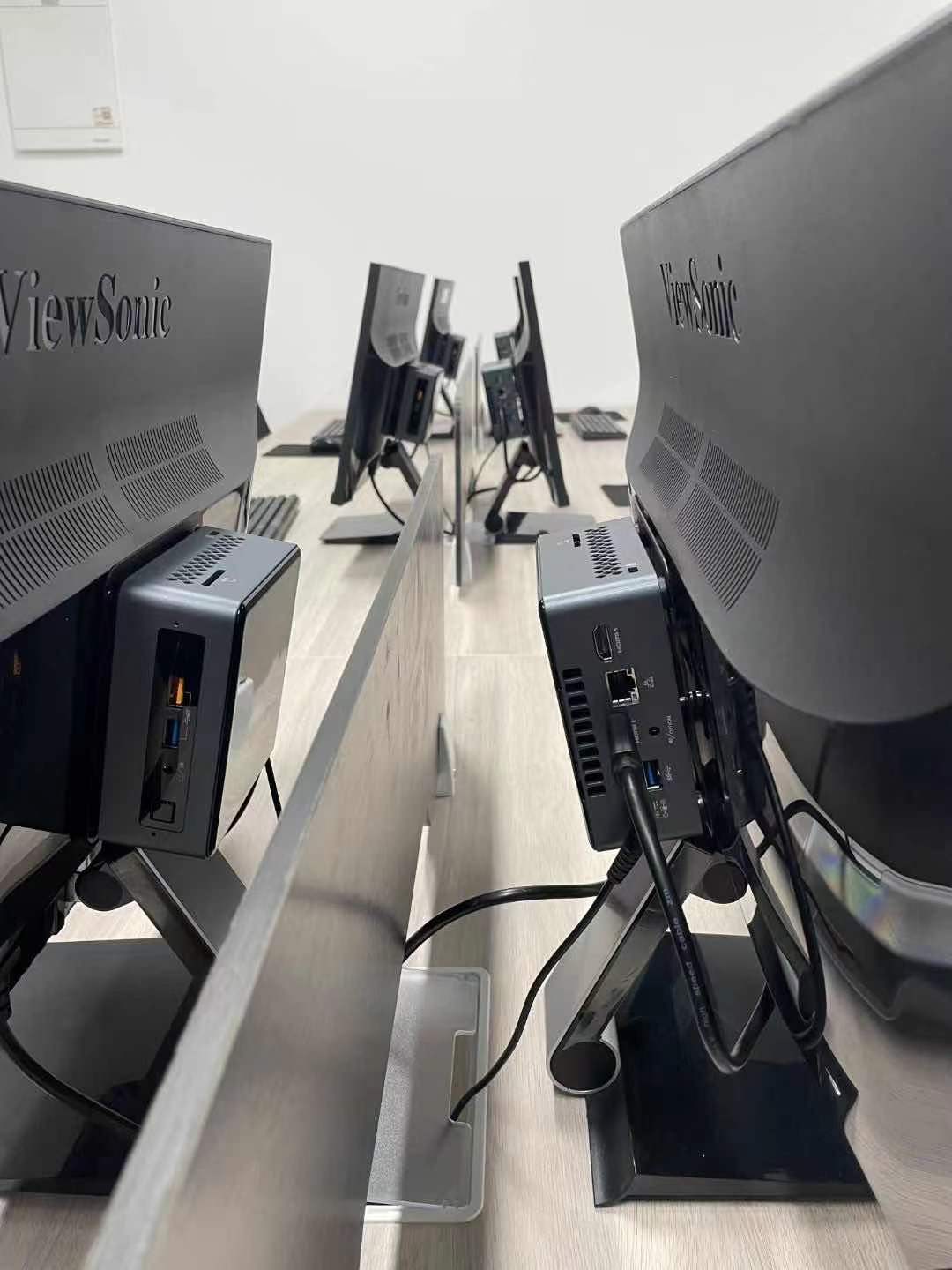

Higole power transmission automatic fault detection system, with industrial control integrated computer as the main hardware of the system, can detect the environmental temperature, humidity, wind speed of the transmission line, ice coating, temperature, galloping condition of the wire, and the inclination of the tower. The sensors of the data acquisition terminal are responsible for collecting the values of these sensors, and transmit the collected values to the industrial computer through the RS232 serial port of the industrial computer computer, and then transmit the data to the central server by the wireless data transmission terminal. The received data is processed and analyzed, so as to grasp the specific condition of the transmission line at each monitoring point, and make corresponding preventive or emergency treatment