Handheld Rugged Industrial Tablet PC Factory Management Case

The informatization of factory management is the trend of modern factory management. With the continuous development of information technology, especially the application of information network, in the daily operation of the factory, there are many kinds of raw materials, small size, troublesome inventory of the amount of in and out of the warehouse, and in and out of the warehouse. There are many classifications and low accuracy of data collection. If you still use manual data inventory, it will greatly increase the number of information collection personnel and information input personnel, and reduce the accuracy of information and the efficiency of the information system. Many international multinational enterprise groups in the world's industrial development have many factories in many regions around the world. How to truly improve factory management efficiency, ensure the accuracy of inventory, and appropriately reduce labor costs is an urgent need and challenge at this stage.Handheld Rugged Industrial Tablet PC Factory Management Case

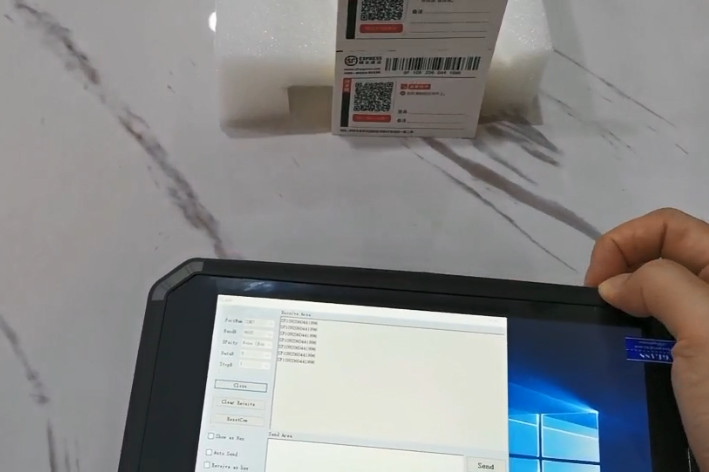

In response to the management needs and challenges of large-scale enterprises, Qianhai Gaole recommended a rugged three-proof tablet F7/F7R, which can automatically collect data from various operations such as warehousing, exporting, returning, and inventory. Assist warehouse managers, feeders and other types of work to complete daily work, and synchronize the collected information to the background system in real time to ensure the efficiency and accuracy of data input for each operation link of the factory management, and ultimately achieve paperless and high-efficiency The data-based operation mode of the company ensures that the company can grasp the real data of the inventory in a timely and accurate manner, and reasonably maintain and control the company’s inventory.

The previous factory management relied on a non-automated, paper document-based system to record and track incoming and outgoing goods, and the internal management of the warehouse was implemented with human memory. For the entire factory, the uncertainty of human factors led to labor The efficiency is low, the time for information transmission is slow, and the inventory data is inaccurate, wrong order, and missed order caused by human factors from time to time.

With the development of enterprises, the import and export of raw materials, the increase in inventory varieties and quantities, and the rapid increase in the frequency of in and out of the warehouse, the traditional operation mode cannot meet the requirements of fast, accurate and real-time factory management. If business leaders cannot grasp the inventory situation in time, it will affect Enterprises rationally arrange production, leading to a large backlog of some products and increasing storage costs. With the miniaturization of industrial tablet computers, and when the wired or wireless scanning gun is used to count the goods, the inventory of the goods does not need to move all the goods to the computer for scanning. It is directly scanned by the handheld tablet computer with the scanning head function, which is convenient Quickly enter data information into the system.

The Higole handheld tablet computer combines the application of barcode technology to realize automatic data collection, eliminating the steps of manually writing receipts and sending them to the computer room for input, which can greatly improve work efficiency. In daily use, a large amount of paper text information required for receipts Converted into electronic data, the staff no longer need to manually browse and find various registers and receipts, just enter the query conditions, and the required records will be found. The front-line staff will upload the data collected on the spot through the industrial tablet computer and update it automatically. The data in the system allows managers to understand inventory information in time, make management decisions in time, and realize visualized management.